On a recent trip to LA, I visited the Nudie Jeans flagship store, the first of it’s kind in West Hollywood. The visit turned into an awesome discusson on denim, fit, and Sweden (Where Nudie hails from). After learning from the best in the trade, Chris and Phil; two denim connoisseur that take serious pride in their profession, I felt it necessary to spread some knowledge about denim to those of you who were in my shoes and didn’t really have a clue.

Nudie Jeans was founded in Gothenburg, Sweden, by Maria Erixsson, and now sells in over 20 countries. Most of you have probably heard of Nudie Jeans, and although I am a huge fan of the company and their product, it becomes extremely interesting when you dive into how their denim is made and what procedures are taken in creating such a beautifully finished product. As Phil started to walk me through all the different fits, treatments and constructions, one thing became certain; I had a hard time keeping up with him. Words I have heard used over and over, are (Dry, Selvage, Slow, Japanese Selvage) I always acted as though I knew exactly what these terms meant and nodded along knowingly, but it was evident that I was overdue for a lesson. Chris Adams quickly brought me up to speed:

Dry Denim, is when the denim isn’t washed after the fabricating and dying process. Breaking in a pair of dry denim jeans involves NOT washing them for up to 6 months or a year. Where the jeans come to life is as you wear them, the fabric starts to fade, crinkle, and crease in the areas specific to your body. You get a custom look specific to your lifestyle and how you wear your jeans.

Selvage Denim, doesn’t have anything to do with salvaging anything, the word “selvage” comes from the phrase “self-edge”, the natural edge of a roll of fabric and instead it is denim made on old-style shuttle looms and selvage comes from how the fabric is woven using once continuous cross thread; the weft. As the the weft loops back into the edge of the weave the selvage edge is created.

Slow, production is much slower than conventionally produced denim, and only the best raw materials are used, thus making it more expensive. The slow speed of the loom causes less stress on the yarn makes the hand of the denim softer and the fabric more durable.

Japanese Selvage, seems to be one the top of line types of denim. Japanese denim is known for being high quality and for often using longer cotton fibers so that the threads don’t have to be twisted as much. This gives the material a softer hand feel as apposed to rougher denims that use shorter length cotton fibers. The Japanese also have access to the shuttle looms so you get a more durable less rushed denim. The dying processes are also finished without a wash allowing for the consumer to customize their jeans with wear.

Nudie Jeans became more of an experience than any other denim shopping i’ve done and its amazing to see the difference when you purchase a high quality fitted jean as aposed to what i’ve been wearing in the past. I love the idea of learning about a product before you buy it, the result is an appreciation for a craft that can go unnoticed and also elicits a confidence and pride in what you wear everyday.

a close up look at a pair of After Treated masterpieces.

clean lines and durable orange stitching is a Nudie signature.

Phil is a denim Genius and these guys also know their coffee.

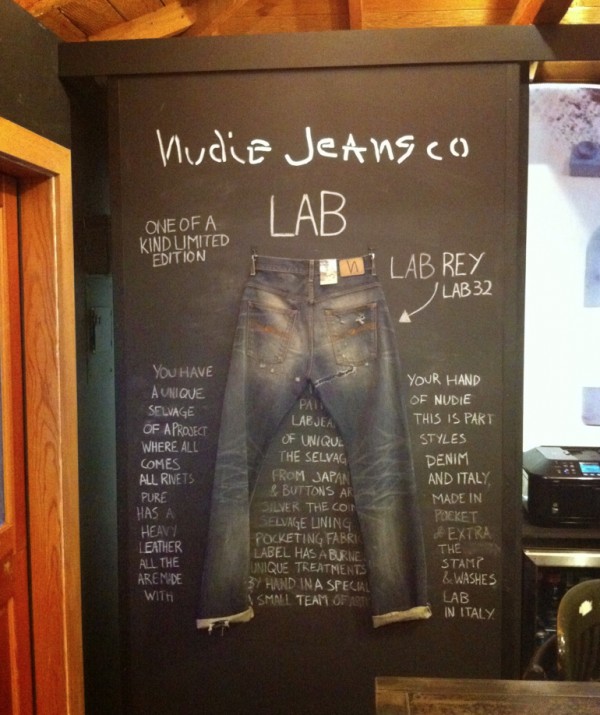

a sneak peak into the Denim Labs.

visit Nudie Jeans online

visit their store in Hollywood